The AR is a modular rifle system wherein the upper half connects to the lower half via two pins. The front pin is known as the “pivot pin” because when the rear pin is opened, the upper half can pivot up allowing for maintenance or to allow the operator to open the pivot pin also and entirely remove the upper for a different model thus allowing tremendous versatility. This is why AR owners can readily swap calibers, barrels, etc. to really tailor their weapon to the task at hand.

Now, when it comes to assembling the lower, there is one big headache when installing the front pivot pin. To keep it from falling out, there is a spring and a tiny detent pin in front of it that will want to launch like a rocket across the room if you aren’t careful. This is one step where I would tell you to wear eye protection – you may think this is a joke but it honestly is not. That detent is tiny and it seriously can come flying out. Some day if I clean out my shop, I will find a handful of these springs and detents hidden from when the flew across the room.

Let me give you a big tip – detent springs and pins are very cheap. Buy spares for those “where the heck did it just go” moments that inevitably happen. You get tired, your mind wanders and then it’s Houston we have a launch! I keep spares – plural – of all small AR parts in my AR parts bin.

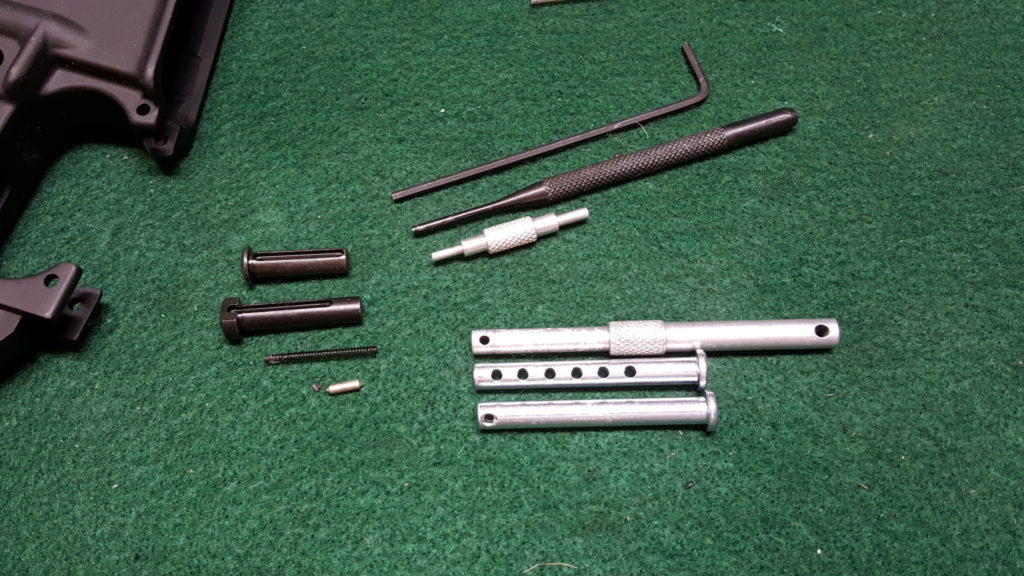

Don’t even think about trying to install that pin without a tool to help. I am going to give you a real strong recommendation – buy a pivot pin assembly tool or at least buy a 1/4″ universal clevis pin if you are just doing a single build. The purpose-built tools are dirt cheap and you can find them everywhere – Amazon, Brownells, Primary Arms, Midway USA, etc. I think I bought my first off eBay but I have several because several armorer’s kits I have bought over the years included one. They all basically look like this:

If you don’t want to spend the money on the tool, a 1/4″ clevis pin works just fine. A regular 1/4″ clevis pin is $0.95/ea and a universal pin is a $1.50 at my local Ace Hardware & either will work just fine. You then use a punch or an allen/hex wrench to push the detent and spring down. Some of the commercial tools on the market are nothing more than a clevis pin with an allen key so it is up to you as to which to use. Note, if you go the clevis pin route, just go to your local hardware store and get one. They are a fortune on Amazon unless you are buying in bulk. For example, $6 for one from some sellers or $13.50 for 10 from others.

There are two sizes to reflect the two types of receivers that are out there and most AR receivers will use the smaller 1/4″ end. The bigger pin was a Colt ban-era move they did to try and prevent a M16 upper from being put on a sporting lower. For anyone doing a build today with a current upper and lower – it will be the 1/4″ size. You will see there are two pins with your lower build kit, The relatively flat one is for the rear and the one with the large shoulder is the front pivot pin. So in the next photo, the pivot pin is the lower pin. You can also see the small double ended detent – either end can be first down the hole – and one of the detent springs. Both takedown pins use the same detent and spring. By the way, I recommend buying one of the reputable spare parts kits and throw it in your tool box just in case. I can’t tell you how many springs, pins and small parts I have dropped and lost over the years.

To make life interesting, a detent spring is inserted into this receiver hole followed by a detent pin on top of it. The detent pin is what actually makes contact the pivot pin. This is always the case with AR rifles and it makes sense. If the spring contacted a rotating pin directly it would break down over time. In terms of pins, I prefer enlarged takedown pins. The ones I use the most are Yankee Hill Machine (YHM) pins that I get at Brownells. They just make it easier for me to disassemble whatever rifle or pistol I am working on.

The actual installation is very straight forward if you have tool or clevis pin. Push the tool in so the hole of the tool is over the hole in the receiver and then insert the spring and the detent pin. The pin will stick up some so you then push it down with the little plunger tool. Simply rotate the tool and the spring and pin are adequately captured – now leave the tool there for the next step. Note, in the photo with the spring, it is at an angle just for the photo. To drop in, everything is straight up and down the axis of the receiver. Also, wear eye protection – if that detent pin comes flying out, you don’t want it to hit you in the eye!

I always grease the channel in the pivot and rear takedown pin so they can slide easier. I like Tetra Gun Grease so that is what you see in the photo but you could use whatever grease you prefer. Always keep the old saying in mind – if it slides, grease it. If it rotates, oil it.

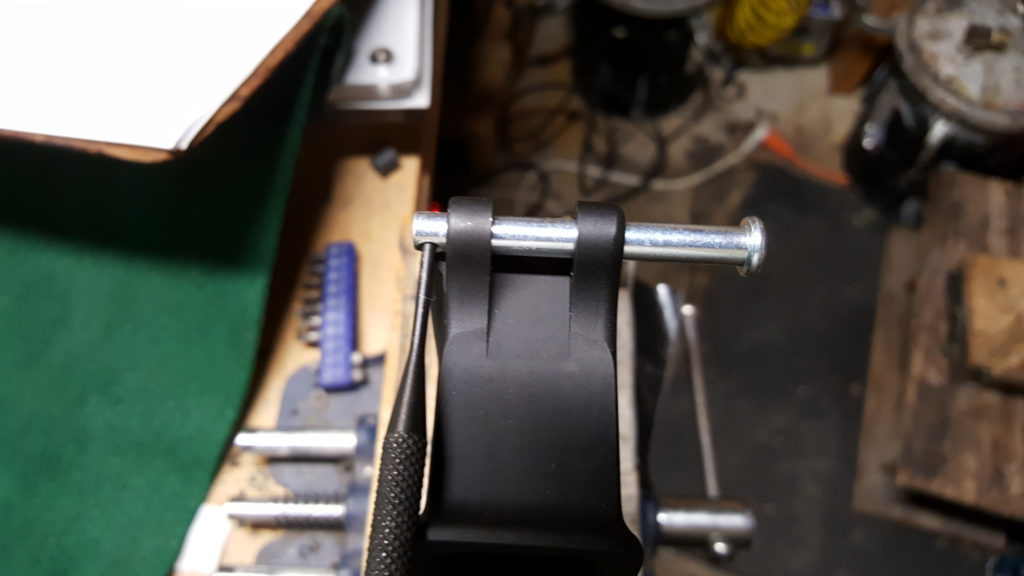

Now this is the only tricky part left. If you have not done so already, remove the plunger so the tool can slide back out but leave the main part of the tool in place with the spring and detent pin captured. Take the pivot pin with the channel facing up (so the pin will not engage it), carefully line it up with the tool, push down and forward to slide the tool out and replace it with the pivot pin. You need the slight downward pressure to keep the detent pin and spring from flying out. Once you see the pivot pin coming through the left lobe/hump, you can remove the tool and rotate the pivot pin into final position with the detent pin riding in the channel.

That’s it! The pivot pin should slide open and closed with the detent catching at either end. Note, this may be a tight fit as the parts wear in. I would not recommend sanding the pin or reaming the hole unless you know for sure the hole is out of spec. Grease the pin and work it in and out. It should loosen up with time as the parts get to know each other.

For folks who choose to do this with a clevis pin, it is the same procedure but with the clevis pin and a punch or allen key to do the work. These next photos are just so you can get an idea of how it works. I simply grab whatever punch or allen key that will fit down the hole of the clevis pin to serve as the plunger. I didn’t grease the mil-spec pin as I just did this to take photos. Here I am just using a plain $0.95 clovis pin and a small punch to serve as the plunger. If I had rotated the pivot pin at the end, it would have been a done deal but I took it back apart as I will use the YHM pin when I decide how I want to build this next lower.

So this step is done! I hope it helps. In the next step I’ll install the trigger assembly.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

AR Parts Sources

There are a lot of reputable AR parts vendors online but beware of eBay and bargain basement dealers that sell airsoft parts and tell you they will stand up to firearm use – they will not. At any rate, here are my top sources of AR parts: