Okay folks, with all the sanding of plastic I do, my shop has tons and tons of dust in it. In 2015 I read an article about how small fine dust particles are unhealthy – in general, the smaller the particle, the more it gets to places in your lungs where you don’t want it to and it may get stuck there. Now I may be a slob, as my wife will readily agree, but I do get concerned about safety. Now I investigated improving my dust collection off the tools and that was way too expensive.

At some point I will upgrade my dust collection at the tools but that will have to wait. What you will notice when talking to a lot of the vendors, and Grizzly is one example, is that they only warranty their products for wood. What this tells you is that they are using open bearings (not sealed bearings) and if other materials get in there (like my glass reinforced plastic), it will shred them. Grizzly product support was real cool about answering my questions and cautioning me up front before I dropped a big amount of cash on one of their dust systems so kudos to them for being up front and honest.

Fine air filter systems are supposed to be on layer of a multi-layered defense but at this point, I was really worried about were the fine particles as I already have some basic dust management in place. In addition, I always wear a quality Moldex 2310 N99 particulate respirator when drilling and sanding but all that junk was just floating around and getting on stuff in the shop, etc. So the immediate need was to get rid of that fine dust. I did some digging and there is a model of suspended fine air filter that seems to be sold under many brand names. I did some digging on Amazon, read the reviews and went with the Wen 3410. Just to be clear, I actually bought this – you are reading a review from a real user and not someone who got something for free in exchange for a review.

The unit arrived on November 9, 2015, and I have used it a ton – replacing both the outer and inner filters many times. Let me tell you a bit first.

Before I did anything, I plugged the unit in and tested it. I learned years ago not to do a ton of work installing something and then test it! Test it up front so it is easy to send back or get tech support on the line and work on it.

I figured out where I wanted to hang the air filter and bought some heavy sign chain from Ace Hardware so I could get it just where I wanted it. The unit isn’t very heavy but given me and some expensive tools would be right under it, I went for overkill. It’s around 30 pounds and the chain is around 120 pounds if I recall right. At any rate, I hung the unit and adjusted the hooks until I got it level. I then ran an extension cord over to it and turned it on. It was a tad loud on the highest setting but definitely something I could live with – I usually have the stereo cranked in my shop anyways so that wasn’t a big deal.

The unit comes with a remote for turning the unit on and off, setting the speed (low, medium or high) and whether to use a timer setting for 1, 2 or 4 hours. I really like the timer as I can have it set to constant on while I am in the shop and then set it to the timer so that it can keep cleaning the air after I leave to get remnants out of the air. Truth to tell, the remote’s battery door has been the only casualty since I bought it. The little tab that held the battery cover in place was never very firm so I resorted to a couple of layers of black electrical tape wrapped around the remote and have never had a problem since.

What I noticed over the coarse of the next few days was that stuff in the shop was not getting a thin layer of dust on it like it was in the past. The unit has an outer coarse filter that is 5 microns and an inner filter at 1 micron. It’s good that it is two stage like that as you can see them both getting filled with dust or at least I can. I probably make it about 2-3 months before I have to change the outer filter and in general I make it about two outer filter changes before I change the inner filter. The life of the filter really depends on how much sanding I am doing and the material I am working with. Once I saw all the crap in the filters, it made me realize that some percentage of that junk was going in my lungs – probably more than I knew.

The next photo is telling – this is the exhaust side of the Wen. After using the unit for over a year with a ton of hours, look how clean it is. I have never cleaned it. That gives you an idea how effective the filters are.

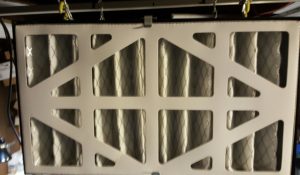

I go by the looks of the filters as to when I change them and I definitely keep spares on hand. The Wen brand filters come in two packs and I’ve noted some of the sizes in case you want to try other brands of external filter. For example, I used a few Powertec 421x241x45, 5 micron external filters worked fine. In general, I try to use Wen. I have only used Wen for the internal 1 micron filter but have seen other identical looking filters but have not tried them. Note how white a new filter is (that is a new Powertec in the machine) vs. the filthy used one sitting on the blast cabinet.

So, I am very happy with the Wen and am actually thinking about a second for the other end of the shop. If you are looking for a fine air filter, I’d recommend this one for sure.

2/22/2018 Update: The Wen is still going strong. No problems at all and I’m still very happy with it.

1/2/2019 Update: Still going strong. No problems.

5/21/2019 Update: Still using it all the time. This has really held up great.

2/19/20 Update: Still holding up great. Just replaced all the filters.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.