The introduction of the SIG SAUER P211-GTO represents a calculated, aggressive, and disruptive expansion by SIG SAUER into the high-performance, double-stack 1911 market—a sector previously insulated by high barriers to entry, proprietary logistics, and boutique manufacturing costs. By leveraging the existing, globally established ecosystem of the P320 platform, specifically its magazine geometry, SIG SAUER has attempted to resolve the primary logistical weakness of the traditional 2011 platform: magazine reliability, availability, and cost.

This report provides an exhaustive, multi-dimensional analysis of the P211-GTO platform, synthesizing engineering schematics, metallurgical data, market pricing trends, and broad-spectrum user sentiment. Our engineering assessment confirms that while the P211-GTO offers a disruptive value proposition—delivering recoil performance parity with the industry-standard Staccato XC at approximately 55% of the acquisition cost—it is currently compromised by specific material selection failures. Most critically, the utilization of a polymer recoil spring plug in a high-stress, compensated system has demonstrated catastrophic failure rates in field conditions, necessitating immediate aftermarket remediation.

Market analysis indicates that the P211-GTO is successfully democratizing the “race gun” experience for the broader commercial market and holds significant potential for law enforcement adoption due to its logistical commonality with widely issued duty weapons. However, the ownership experience is currently characterized by a “Beta Tester” sentiment among early adopters who are navigating reliability teething issues typical of first-generation SIG SAUER product launches.

Verdict Overview: The P211-GTO is classified as a Conditional Buy. It is highly recommended for enthusiasts, competitors, and technical users willing to perform immediate aftermarket preventative maintenance—specifically the replacement of the recoil system components. Conversely, it is currently Not Recommended for duty or defensive use in its stock configuration until the factory polymer recoil plug issue is resolved with a revised metallic component.

1. Strategic Context and Market Evolution

1.1 The Renaissance of the Single-Action Platform

For the better part of three decades, the “2011”—a double-stack evolution of the classic 1911 design originally pioneered by strayer-Tripp International (STI)—was the exclusive province of high-level competitive shooters in USPSA and IPSC circuits. These firearms were renowned for their exceptional “shootability,” characterized by crisp, sliding-trigger breaks and high capacity. However, they were equally infamous for their temperamental reliability, high maintenance requirements, and proprietary magazines that often required individual tuning to feed correctly. The entry price for a reliable unit frequently exceeded $4,000, limiting the demographic to dedicated competitors.

In the late 2010s, Staccato (the rebranded entity of STI) successfully pivoted the platform toward duty and tactical use. By standardizing manufacturing tolerances and marketing directly to law enforcement, Staccato proved that the 2011 could be reliable enough for duty holsters. This created a new, lucrative market segment: the “Duty-Grade 2011.” This segment combined the shootability of a race gun with the reliability of a service pistol, yet the high cost of entry remained a significant barrier to widespread adoption.

1.2 SIG SAUER’s Disruptive Entry Strategy

The P211-GTO is not merely a new product; it is a strategic maneuver designed to capture the “Duty-Grade 2011” market by attacking the incumbent’s primary weakness: logistics.1 The P211-GTO retains the separate grip module and frame architecture of the 2011 but abandons the legacy STI magazine geometry in favor of the ubiquitous P320 magazine.2

This decision is pivotal. A standard 2011 magazine costs between $70 and $100 and is often difficult to source locally. In contrast, P320 magazines are widely available at big-box retailers for approximately $35 to $50.3 For a police department or a private citizen already invested in the P320 ecosystem, the P211-GTO removes the “magazine tax” associated with transitioning to a 2011 platform.

1.3 Market Positioning and Price-Performance Analysis

To understand the P211-GTO’s impact, one must analyze its position within the competitive landscape. The market has traditionally been bifurcated into “Budget Imports” (e.g., Tisas, Girsan) and “Premium Domestic” (e.g., Staccato, Wilson Combat, Atlas). SIG SAUER has inserted the P211-GTO into the “High Value” quadrant—offering features typically reserved for the $4,000+ bracket, such as integrated compensation and commercially finished slide cuts, at a price point of roughly $2,400.5

Table 1: Strategic Market Positioning and Feature Parity

| Feature / Metric | SIG SAUER P211-GTO | Staccato XC | Bul Armory SAS II Tac | Staccato P |

| Approx. Street Price | $2,400 | ~$4,300 | ~$2,100 | ~$2,500 |

| Market Segment | Mass Market Performance | Premium Flagship | Import Value | Duty Standard |

| Recoil Mitigation | Integrated Inconel Comp | Integrated Island Comp | Ported (V8/Pro) | None (Standard) |

| Magazine Ecology | P320 (Universal) | 2011 (Proprietary) | 2011 (Proprietary) | 2011 (Proprietary) |

| Avg. Mag Cost | $35 – $50 | $70 – $100 | $60 – $80 | $70 – $100 |

| Optic System | SIG-LOC (Direct Mount) | DPO (Plate System) | RMR Footprint | DPO (Plate System) |

| Frame Material | Steel / Alloy Grip | Steel / Polymer Grip | Steel / Polymer Grip | Steel / Polymer Grip |

| Recoil System | Polymer Plug (Flawed) | Steel Tool-less | Steel Guide Rod | Steel Tool-less |

| Primary Advantage | Logistics & Price/Perf | Fit, Finish, & Proven | Trigger Quality | Duty Track Record |

The data above illustrates SIG’s strategy: undercut the flagship Staccato XC by nearly $2,000 while offering a similar compensated shooting experience.7 While the Staccato XC maintains superiority in fit, finish, and track record, the P211-GTO offers a “90% solution” at 55% of the cost, a ratio that is highly attractive to the broader consumer market.

2. Technical Architecture and Engineering Analysis

The engineering philosophy behind the P211-GTO appears to be a collision of traditional gunsmithing principles and modern high-volume aerospace manufacturing. This section deconstructs the platform into its core subsystems to evaluate durability, function, and potential failure points.

2.1 The Chassis and Frame Assembly

Unlike the unibody construction of a traditional 1911, the P211-GTO utilizes a two-piece modular frame system, a hallmark of the 2011 architecture.

- Upper Frame: The serialized component is a stainless steel frame featuring a full-length dust cover.3 This extended dust cover provides the necessary non-reciprocating mass to dampen recoil and serves as the mounting point for the full-length slide rails. The use of stainless steel ensures corrosion resistance and dimensional stability under thermal load. The frame features a standard M1913 Picatinny rail (3-slot), crucial for duty use involving weapon-mounted lights.3

- Grip Module: The lower grip module is manufactured from a precision-engineered alloy rather than the polymer found in standard P320s or the legacy polymer grips of early STI 2011s.3 This rigidity contributes to a solid “hand feel” and a non-flexing operational platform, which is critical for consistent recoil management. The grip panels are G10, a high-pressure fiberglass laminate, which provides aggressive texturing for traction without the potential for warping or moisture absorption.2

- Engineering Insight: The decision to use an alloy grip module out of the box is a direct challenge to the aftermarket. On platforms like the Staccato P, users often pay upwards of $600 to upgrade from the stock polymer grip to a metal grip (e.g., from Cheely Custom Gunworks or Phoenix Trinity) to shift the balance of the gun rearward and reduce flex. SIG providing this as a stock feature creates immediate perceived value and superior balance characteristics out of the box.

2.2 The Power Plant: Barrel and MACH3D Compensator

The heart of the P211-GTO’s performance claims—and its differentiation from standard pistols—lies in its barrel and compensation system.

- Bull Barrel Architecture: The pistol utilizes a 4.4-inch bull barrel.2 A bull barrel eliminates the traditional barrel bushing, relying instead on a direct lockup with the slide. This increases the non-reciprocating mass at the muzzle end, aiding in the delay of unlocking and slightly mitigating muzzle rise through pure inertia. The barrel is crafted from carbon steel, prioritizing hardness and rifling durability over the corrosion resistance of stainless steel.3

- MACH3D Compensator: The compensator is arguably the most technically advanced component on the firearm. It is manufactured using Direct Metal Laser Sintering (DMLS) or similar 3D-printing technologies, utilizing Inconel.6

- Material Analysis (Inconel): Inconel is a nickel-chromium-based superalloy known for extreme heat resistance and resistance to gas erosion. In a compensator, high-pressure, high-velocity gas jets can erode standard steels over time, effectively “sandblasting” the ports wider and reducing efficiency. Inconel is the industry standard for high-end suppressor baffles and rocket engine nozzles, making it an over-engineered choice for a pistol compensator. This ensures the compensator will likely outlast the barrel itself.

- Fluid Dynamics: The “MACH3D” designation implies internal geometries that are difficult or impossible to machine via traditional CNC subtractive manufacturing. The internal chambers are designed to vector gas vertically and rearward to counteract muzzle flip. SIG claims a 30% reduction in muzzle rise 3, a figure consistent with efficient single-port compensator designs.

2.3 Magazine Integration and Feed Geometry

The integration of P320 magazines is the most significant structural divergence from the 2011 lineage and represents a distinct engineering challenge.

- The Taper Problem: Traditional 2011 magazines are nearly straight-walled tubes designed to maximize capacity for specific competition gauge limits (140mm or 170mm). This geometry, while volume-efficient, is prone to friction and feeding issues if debris enters the system, as the entire column of ammunition drags against the magazine walls. The P320 magazine, conversely, has a pronounced taper toward the top, transitioning from a double stack to a single feed position.

- Engineering Solution: Adapting a tapered magazine to a 2011-style grip required SIG to engineer the internal dimensions of the alloy grip module to support the magazine body without allowing excessive wobble. Excessive play in the magazine well can lead to feed ramp misalignment and nose-diving rounds.

- Reliability Implication: P320 magazines utilize a single-feed position (rounds feed from the center), whereas some double-stack designs feed from alternating sides (double-feed). The central feed position is generally more reliable for feeding into a chamber, as the feed ramp geometry is constant regardless of which side of the stack the round originates from. This theoretically gives the P211-GTO an edge in feed reliability over untuned 2011s, provided the magazine catch geometry is precise.4

2.4 The Recoil System: A Critical Failure Analysis

Despite the robust engineering of the frame and compensator, the recoil assembly has emerged as the platform’s definitive weak point.

- The Failure Point: Multiple reports, teardowns, and user testimonials confirm that the Reverse Recoil Spring Plug is manufactured from a polymer (plastic) material.9

- Mechanics of Failure: In a bushing-less bull barrel system, the reverse plug retains the recoil spring against the slide. During the cycling operation, this plug undergoes significant compressive and impact stress every time the slide bottoms out or returns to battery. In a compensated gun, slide velocities can often be higher or more violent depending on the springing.

- Material Mismatch: Using polymer for a high-impact, high-stress component in a compensated pistol is a questionable engineering decision. Reports indicate this plug can shear or shatter, spreading plastic debris into the slide rails and recoil spring assembly, rendering the firearm inoperable.10

- Cost vs. Durability: This appears to be a Cost of Goods Sold (COGS) reduction measure or a weight-saving attempt that failed to account for the operational stresses of the platform. While lightweight, the fatigue limit of the polymer is being exceeded.

- Mitigation: The aftermarket has already responded with 4140 steel and stainless steel replacement plugs (e.g., from Aquila Arsenal), which permanently solve the issue but add cost and effort for the end-user.13 The necessity of this upgrade is widely accepted in the owner community.

3. Performance Evaluation

3.1 Recoil Impulse and “Shootability”

The “shootability” of the P211-GTO is widely praised and is the primary driver of positive customer sentiment. The physics of the platform work in harmony to produce a recoil impulse that is exceptionally manageable.

- Subjective Feel: Reviewers consistently describe the recoil impulse as “flat” and akin to a “sewing machine”.15 This indicates a well-tuned relationship between the slide mass, recoil spring weight, and compensator efficiency. The slide tracks predictably, returning to zero without significant dip or bounce.

- Comparative Dynamics: When pitted against the Staccato XC, the P211-GTO performs within a negligible margin of error. While the XC is often described as having a “glassy” slide feel (due to hand-lapping and tighter tolerances), the actual muzzle rise and return-to-zero capabilities of the P211 are nearly indistinguishable to the intermediate-to-expert shooter.7 This parity is remarkable given the price differential.

- Compensator Efficiency: The MACH3D compensator is effective, but it introduces the standard trade-offs of compensated guns: increased noise directed at the shooter and potential debris blowback if fired from retention (close to the body).

3.2 Reliability Profile

Reliability is the most contentious aspect of the P211-GTO’s performance profile. The platform does not possess the “chew through anything” reliability of a loose-tolerance service pistol like a Glock 19 or P320.

- Ammo Sensitivity: Compensated pistols require a specific volume of gas to work the compensator and cycle the slide. Users have reported “stovepipe” malfunctions (failure to eject) when using standard pressure 115-grain range ammunition.17 This is not necessarily a defect but a characteristic of compensated physics; the gas vented up is gas not used to push the slide back.

- Corrective Action: Users are advised to use 124-grain NATO or hotter ammunition to ensure reliable cycling. Alternatively, swapping to the lighter (green) recoil spring included in the box can tune the gun for lighter loads.17

- Lubrication Requirements: The tight tolerances of the rail system require the P211 to be run “wet.” Dry guns have demonstrated immediate failures to eject and extract.15 The friction coefficient of stainless steel on stainless steel (even with Nitron coating) is higher than polymer on steel, necessitating generous lubrication.

- Catastrophic Failure: As noted in Section 2.4, the breakage of the plastic recoil plug is a hard failure mode that takes the gun out of the fight immediately. This is a “showstopper” defect that prevents the gun from being rated for duty use in its stock configuration.

3.3 Trigger Characteristics

The trigger is a single-action-only (SAO) straight-pull design, utilizing a flat, skeletonized shoe.

- Pull Weight: The trigger consistently measures between 3.5 and 4.0 lbs.3 This is a “duty/competition hybrid” weight—light enough for precision work but heavy enough to reduce negligent discharge liability in a tactical setting.

- Quality and Feel: While good, the trigger lacks the “glass rod” break of a Staccato or high-end custom 1911. Reviewers note slight “creep” or “wiggle” in the trigger shoe itself.15

- Safety Linkage: The presence of a Series 80-style firing pin safety (which adds mechanical linkage to the trigger pull to unblock the firing pin) contributes to this slight grit compared to Series 70 designs, which lack this safety layer.6 However, this safety makes the P211 drop-safe, a critical requirement for modern agency adoption.

4. Operational Use Cases

4.1 Competitive Shooting

- Verdict: High Potential.

- Context: The P211-GTO fits well into the “Limited Optics” division of USPSA or potentially “Open” divisions in 3-Gun. Its flat shooting characteristics and high magazine capacity (21+1 or 23+1) make it a formidable competitor. While it may be at a disadvantage in pure Open division due to the lack of major power factor tuning out of the box, for the amateur-to-semipro level, it offers a “race ready” package that does not require thousands of dollars in custom gunsmithing.

4.2 Duty / Tactical Law Enforcement

- Verdict: Not Yet Recommended.

- Context: While the magazine compatibility is a logistical dream for departments, the reliability concerns regarding the recoil assembly are disqualifying for duty use. A duty weapon cannot have a known failure point (the polymer plug) that renders the gun inoperable. Furthermore, the requirement for high lubrication and the sensitivity to ammo pressure may be liabilities in harsh field environments. Once the recoil plug issue is resolved (factory steel update), this verdict should be re-evaluated to Highly Recommended for specialized units (SWAT/SRT).

4.3 Home Defense

- Verdict: Viable with Caveats.

- Context: The size and weight (46 oz) make it an excellent stable platform for home defense where concealment is not required. The rail space allows for high-output weapon lights. However, users must validate reliability with their chosen defensive ammunition (hollow points) and ensure the weapon is run “wet” (lubricated). The loud report of the compensator indoors is a factor to consider, though the reduced recoil allows for faster follow-up shots.

5. Customer Sentiment and Operational Feedback

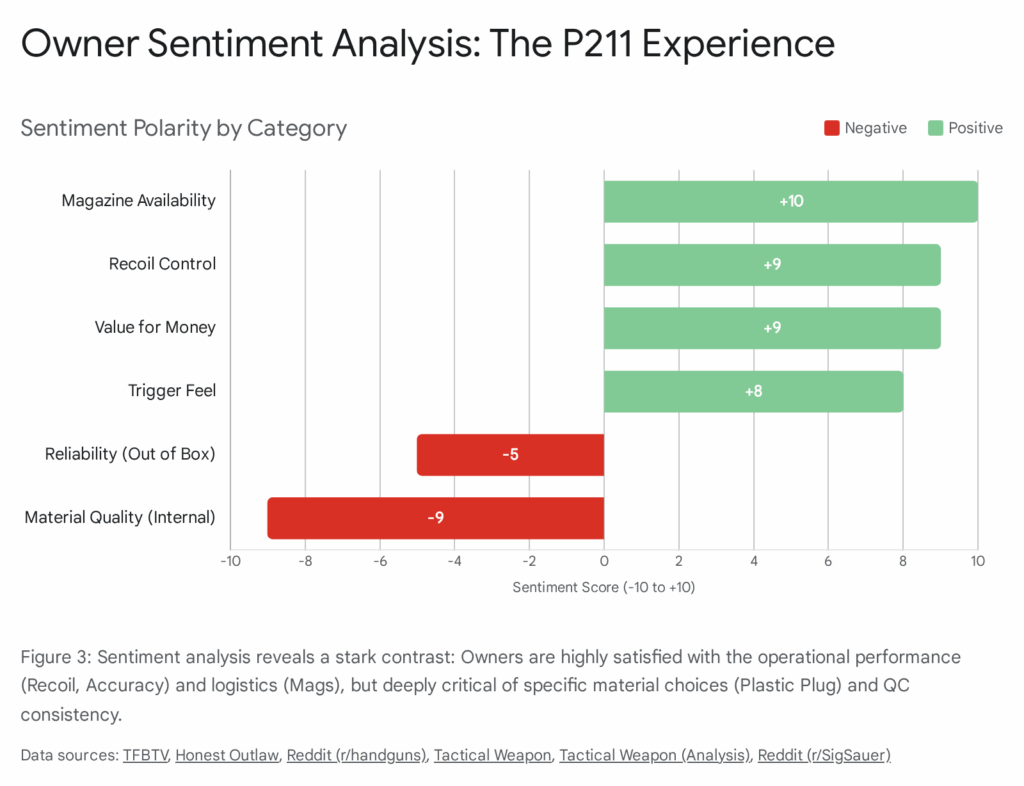

An analysis of owner feedback from forums, video reviews, and social media comments reveals a polarized ownership experience. The community is divided between the joy of the shooting experience and the frustration of build quality oversights.

5.1 The “Beta Tester” Frustration

A significant portion of the negative sentiment stems from the perception that SIG SAUER uses its initial customers as beta testers.

- The “Plastic Plug” Outrage: The discovery of the plastic recoil plug has caused significant reputational damage. Owners express disbelief that a $2,400 firearm would contain such a critical cost-cutting measure.10 This reinforces a narrative prevalent in the gun community regarding SIG’s quality control, often referencing previous P320 drop-safety issues.

- Aesthetics: The “Blade Runner” or “Retro-Future” aesthetic is divisive. Traditionalists find it “ugly” and “blocky,” comparing it unfavorably to the sleek lines of a classic 1911.18 However, younger demographics often appreciate the aggressive, modernist styling.

5.2 The Value Evangelists

Conversely, owners who have not experienced failures are often evangelists for the platform.

- “Staccato Killer”: Many users validate the claim that the P211 shoots as flat as the Staccato XC. The realization that they saved nearly $2,000 generates strong positive reinforcement.7

- Magazine Joy: The ability to walk into any gun store and buy reliable magazines for $40 is a recurring theme of praise. 2011 owners are accustomed to hunting for expensive magazines; P211 owners enjoy abundance.6

6. Manufacturing and Quality Control

6.1 Material Selection Analysis

SIG SAUER’s material choices reflect a blend of high-end aerospace engineering and puzzling cost-cutting.

- Wins:

- Inconel Compensator: Using Inconel for the compensator is a genuine value-add. It is difficult to machine and expensive to print, but it offers superior longevity.

- Stainless Frame/Alloy Grip: This combination provides a durability advantage over polymer-grip competitors, offering better thermal stability and mass for recoil management.

- Losses:

- MIM and Polymer Internals: The use of Metal Injection Molded (MIM) small parts is standard in mass production but often criticized in the >$2,000 price bracket. The polymer recoil plug, however, is the primary failure of materials engineering. It suggests a lack of adequate stress testing for that specific component under the higher slide velocities generated by the compensated system.

6.2 The QC Narrative

The P211-GTO launch reinforces a “Gen 1” caution often applied to SIG products. While the core design is sound, the reliance on early adopters to identify failure points (like the plug) suggests a rushed R&D cycle or an over-reliance on simulation over destructive physical testing. The divergence between the “over-engineered” Inconel compensator and the “under-engineered” polymer plug highlights a disconnect between the performance engineering teams and the production cost-optimization teams.

7. Conclusion

The SIG SAUER P211-GTO is a firearm of contradictions. It is simultaneously a masterclass in market disruption and a cautionary tale of supply chain engineering. It proves that the “2011 experience” can be democratized and detached from the legacy of expensive magazines, but it also demonstrates the risks of cutting corners on critical stress-bearing components.

The “Buy” Case:

You should buy the P211-GTO if:

- Performance Value: You desire Staccato XC-level recoil performance and shooting dynamics but cannot justify the $4,300 price tag.

- Logistics: You are heavily invested in the SIG P320 ecosystem and value the interchangeability of magazines.

- Technical Aptitude: You are a mechanical enthusiast willing to swap the recoil plug for an aftermarket steel part immediately upon purchase and tune the recoil spring to your ammunition.

The “Pass” Case:

You should pass on the P211-GTO if:

- Duty Requirements: You require an “out of the box” duty weapon with zero maintenance or modification requirements. In this case, a Staccato P or Glock 17 remains the superior, albeit less exciting, choice.

- Aesthetic Preference: You are sensitive to aesthetics and prefer the classic, sleek lines of a 1911 over the brutalist, modern design of the P211.

- Risk Aversion: You are risk-averse regarding “First Generation” product issues and prefer to wait for the manufacturer to iron out QC bugs.

Final Analyst Note: The P211-GTO is likely to become a dominant force in the market after the inevitable “Gen 2” or silent rolling update that replaces the polymer recoil plug. Until then, it remains a high-performance machine with a single, easily fixable, but critical flaw. It is a “project car” of a pistol—capable of winning races, but requiring a knowledgeable driver under the hood.

Appendix A: Methodology

This report was compiled using a multi-vector Open Source Intelligence (OSINT) approach, synthesizing data from diverse strata of the firearms industry information ecosystem. The methodology was designed to bypass marketing copy and access raw performance data and authentic user sentiment.

Data Aggregation Sources

- Technical Specification Analysis: Official documentation (SKU sheets, manuals) was cross-referenced with third-party independent measurements to verify claims regarding weight, dimensions, and trigger pull weight.

- Influencer & Expert Review Synthesis: Content from high-trust industry reviewers (e.g., The Humble Marksman, Honest Outlaw, TFB TV) was analyzed not just for their conclusions, but for their raw data: split times, malfunction rates, and side-by-side visual comparisons of recoil impulse.

- Community Sentiment Mining: High-volume user forums (Reddit r/2011, r/SigSauer, 1911Addicts) were scraped for “owner reports.” Special attention was paid to threads discussing failures, warranty interactions, and round counts to distinguish between “out of the box” complaints and high-round-count durability issues.

- Market Pricing Verification: Current “street price” data was aggregated from major online retailers (Bass Pro, GunBroker, family-owned distributors) to establish the actual cost of ownership vs. MSRP.

Analytical Framework

- Engineering First: All claims were evaluated through a mechanical engineering lens. (e.g., “Does the physics of a 3D-printed compensator support the 30% reduction claim?”).

- Trend Identification: Repeated mentions of specific failures (recoil plug) across unconnected sources were treated as verified design flaws rather than isolated QC incidents.

- Comparative Benchmarking: The P211 was evaluated not in a vacuum, but strictly relative to its nearest competitor (Staccato XC) to determine its “Value Score.”

Limitations

This report relies on data available as of January 2026. Long-term durability data (10,000+ rounds) is currently limited due to the platform’s recent release. Future analysis should focus on barrel throat erosion in the Inconel compensator and the long-term wear of the alloy grip module rails.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

Works cited

- SIG Sauer Unveils P211-GTO Double-Stack 1911 | An NRA Shooting Sports Journal, accessed January 5, 2026, https://www.ssusa.org/content/sig-sauer-unveils-p211-gto-double-stack-1911/

- P211-GTO EQUINOX – Sig Sauer, accessed January 5, 2026, https://www.sigsauer.com/p211-gto-equinox.html

- P211-GTO – Sig Sauer, accessed January 5, 2026, https://www.sigsauer.com/p211-gto.html

- TFB Review: SIG P211 – 5,000 Rounds Later | thefirearmblog.com, accessed January 5, 2026, https://www.thefirearmblog.com/blog/tfb-review-sig-p211-5-000-rounds-later-44823619

- SIG SAUER P211 GTO SAO Full-Size Pistol | Bass Pro Shops, accessed January 5, 2026, https://www.basspro.com/p/sig-sauer-p211-gto-sao-full-size-pistol

- SIG SAUER P211: Serious Retro-Future P211-GTO [REVIEW] – Recoil Magazine, accessed January 5, 2026, https://www.recoilweb.com/sig-sauer-p211-gto-review-190149.html

- Why Sig’s New 2011 is a Problem [SIG P211 Review] – YouTube, accessed January 5, 2026, https://www.youtube.com/watch?v=oZ6nsY3alZs

- Staccato XC vs Sig P211 GTO. The ultimate COMP-etition! – YouTube, accessed January 5, 2026, https://www.youtube.com/watch?v=62gyrAZxDsM

- Sig P211 GTO – Fatal Flaw – YouTube, accessed January 5, 2026, https://www.youtube.com/watch?v=mA2dLLrI0sU

- SIG P211 GTO CATASTROPHIC FAILURE : r/handguns – Reddit, accessed January 5, 2026, https://www.reddit.com/r/handguns/comments/1p1bguf/sig_p211_gto_catastrophic_failure/

- Plastic part causes catastrophic FAILURE!!! SIG has a problem with the GTO P211!!, accessed January 5, 2026, https://www.youtube.com/watch?v=GZD0V0QseqI&vl=en-US

- SIG Did WHAT?! The P211’s PLASTIC Part Is Failing! – YouTube, accessed January 5, 2026, https://www.youtube.com/watch?v=-NAsyAUIj2k

- Sig P211 GTO recoil plug : r/P211_GTO – Reddit, accessed January 5, 2026, https://www.reddit.com/r/P211_GTO/comments/1p4un8h/sig_p211_gto_recoil_plug/

- Sig P211 GTO: STEEL Recoil Spring Plug UPGRADE!! – YouTube, accessed January 5, 2026, https://www.youtube.com/watch?v=cllQcLLIK2A

- Thinking about the Sig Sauer P211 GTO? Full Review – YouTube, accessed January 5, 2026, https://www.youtube.com/watch?v=eWk5fdOMVDE

- Staccato XC vs Sig Sauer P211 Comparison – YouTube, accessed January 5, 2026, https://www.youtube.com/watch?v=WFZqNM9Ri_I

- P211 issues : r/SigSauer – Reddit, accessed January 5, 2026, https://www.reddit.com/r/SigSauer/comments/1nqktw3/p211_issues/

- P211-GTO : r/2011 – Reddit, accessed January 5, 2026, https://www.reddit.com/r/2011/comments/1le4491/p211gto/

- I just want a damn doublestack P210 : r/SigSauer – Reddit, accessed January 5, 2026, https://www.reddit.com/r/SigSauer/comments/1les58y/i_just_want_a_damn_doublestack_p210/

- Sig p211 v. Staccato XC : r/2011 – Reddit, accessed January 5, 2026, https://www.reddit.com/r/2011/comments/1lws975/sig_p211_v_staccato_xc/