Ok, in August 2024, I realized my old Harbor Freight (HF) 38142 13″ bench top drill press was having real issues. I always thought the switch would die or maybe the motor but it was actually the bearings in the spindle. It could no longer drill an accurate hole – runout was horrible and the whole spinde would deflect on angled work pieces.

Now, I need to be fair – the HF drill press lasted me from some time around 1998 all the way to late Summer 2024. Thousands of Ronin’s Grips AK and Galil grips had been drilled there and and it takes three drilling operations per grip so that is a ton of drilling. I can’t even begin to guess what all else I have drilled over the years – gun parts, car parts, stuff for the house … Yeah, I’m not going to bash the Harbor Freight press. The challenge was that I needed a new press, wanted something that was relatively accurate and had to do some digging. I ruled out a lot of cheap stuff right away due to a number of factors.

I knew I wanted another bench top drill press – they just fit into my shop easier that way and that’s another story. One thing I needed was a tall drill press to accommodate my jigs for the grips including an X-Y table for precision adjustments. I also wanted one that was accurate, had some power to it and … didn’t have belts. It may sound silly but I hate changing pulleys.

In case you are new to drills, the material you are drilling, size of bit, and type of bit all affect the RPM you should be drilling at and how fast you push the bit into the material. Traditionally, a drill press has the electric motor at the rear and two or three stepped pulleys that let you adjust the RPM. The adjustment is done by opening the top, loosening the motor (usually by pulling a lever) and then moving the one or two belts on the top to the combination of pulleys you want to get the approximate speed you want. It drives me nuts. I guess everyone has things that bug them and this is one of mine. I’d usually run an average speed and adjust my feed speed accordingly which meant I was almost always drilling slower than what I could have been. Also, old belts slipping would introduce another level of joy as the drill bit would bog down and even stop at times. At any rate, it was a pet peeve and I really didn’t want belts so let’s move on.

Because the HF drill press had a 13″ swing (the largest diameter object that can be drilled to its center), I knew I at least wanted that. So, I dug and dug and finally got it down to either a Jet or a Nova Viking model 83700 by Teknatool. After even more digging, I got it down to the Viking. You know what? I’m very happy with it almost two full months in.

“Ok, so why the Viking?” you ask:

- Variable frequency 1 horsepower 120 volt motor (no more belts)

- Very good accuracy – they tell you how to test the runout

- Variable Speed: 150 – 3,000 RPM (programmable to 6,000 RPM)

- Swing: 16”

- Stroke: 4.5”

- Spindle to table: 12-2/3″ (320mm)

- Spindle to base: 22-2/3″ (575mm)

- Drill Chuck: 5/8” (1-16mm)

- Spindle Taper: 2MT

- Quill:4.5” of quill travel

- Weight: 154 pounds … it was definitely not light.

Now, I need to point out that spindle to table measure of 12-2/3″. That actually was too short if I set my XY table and jobs on it. The HF unit had a far bigger maximum spindle to table distance because the base and table collars were far smaller / less beefy than what the Viking has. The way I worked around this was to mount my XY table on the base and not the table and I had to make some of my jigs taller. This actually worked out really well because I can swing the table out of the way and use the XY table for my grips where I need adjustable precision. When I want to drill something ad hoc, I remove the jig from the XY table, and swing the drill’s own table back into position,

The Arrival

Honestly, it arrived in great shape via UPS. I saw the UPS truck pull in and I directed him where to drop it off and helped him. I knew it was going to way a ton and didn’t want him to either drop it or get hurt.

Moving Heavy and Awkward Drill Presses

The first thing I needed to do was to remove the old HF drill press. It weighed in around 100 pounds back and in the day and with my back as screwed up as it is, I needed some way to get it out and whatever I used had to fit in a tight area.

I’d done some research and ordered a Pit Posse PP2551S Motorcycle ATV Scissor Floor Jack Lift Table … Amazon descriptions are often a mile long to squeeze in keywords for searching but bottom line this is a nice small lift. It’s area is about 20″ x 18.5″ and it can go up about 36″ with 300 pounds. I read guys used this to move different stuff besides motorcycles and it worked great. I used it both to remove the old HF and wheel the much heavier Viking into position.

Unboxing and Assembling the Viking Drill Press

| This is the first tool I’ve bought where they require you to install a large surge protector. I’ve always thought it was a good practice to do it, but here they require one that is rated for at least 2900 joules to protect the DVR motor’s electronics. I bought a Tripplite TLP18TTUSBB 12 outlet model to protect it. I worked in IT for many years and Tripplite units never failed us. It is rated for 4,320 joules and has its own insurance for $150,000 of equipment protected. Click here for it on Amazon. Note, if you are installing the drill on a GFI protected circuit, they mention it needs a leak current threshold rating of 300 mA / 0.03 amps so the DVR doesn’t trip it I guess so check your ratings. I don’t have the drill on a GFI circuit so I did not need to worry about that. |

With the old drill press out of the way, it was time to unbox and assemble the Viking. Let me tell you, it’s super easy. You basically bolt the upright portion to the bottom table. Now it was big and awkward so I used the foam packaging to help me lever the assembled until up onto the Pit Posse table.

Testing

Okay, I installed the chuck, inserted a bit and expected magic. Instead, I watched a bit turning in an orbit. In other words, so much runout I could see it and I had a serious WTF? moment. I then followed Teknatool’s guidance and measured runout at various points and everything was within spec except for the chuck. Teknatool has you insert a precision ground rod, and measure runout at 100mm below the chuck.

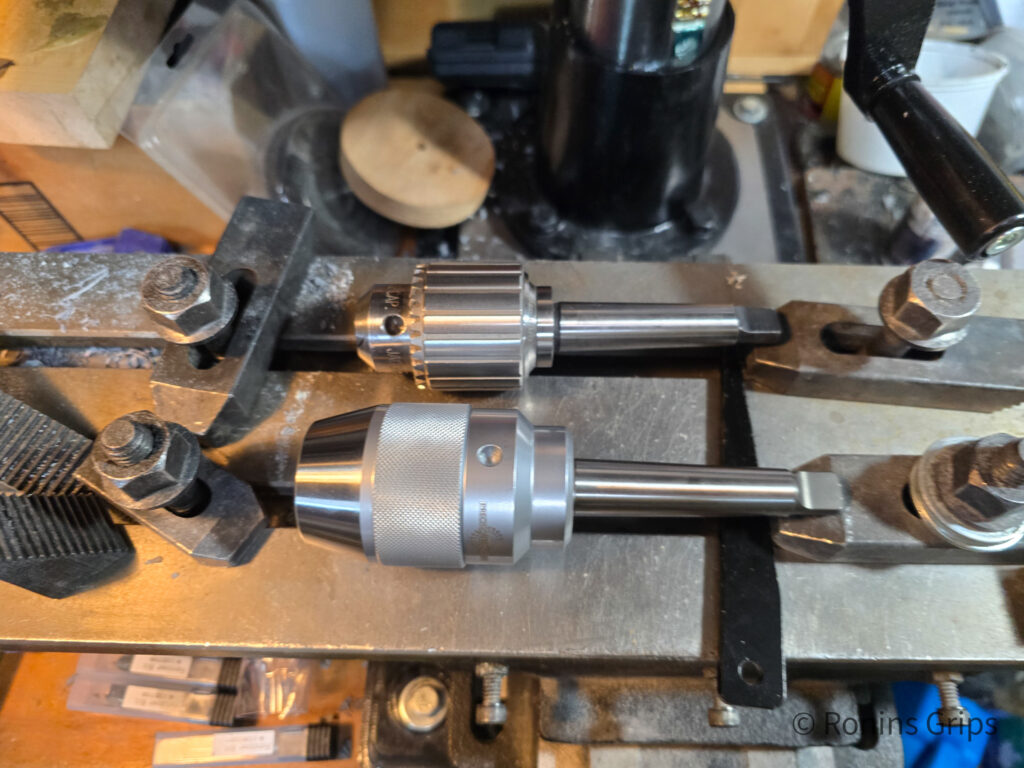

I did some digging at that point and somehow I had missed comments that it was a great drill press with a marginal chuck. I had bought their keyless chuck also so I installed it and still wasn’t impressed. I literally tried five chucks before I settled on the one I am using now. Let’s go through each and the measured runout measured at 100mm below the chuck using a precision ground 1/2″ rod. To be in spec, the target was to be 0.18mm:

| Chuck | Runout | Notes |

| Original Chuck | Awful – didn’t record it. I could see the bit turning in an orbit that is how bad it was. | |

| Nova Keyless Chuck | 0.279mm | Still not happy and am not going to recommend it. |

| Jacobs Model 33 Chuck (I have heard not so good comments about current Jacobs chuck quality so I am not going to link to them) | 0.006mm | I bought this in 2016 and has an integral taper. It’s decent in terms of runout but you must use a key with it and I really wanted keyless. $60 back in the day. |

| Precision Matthews Ultra Precision Chuck (Click here to see PM chucks on eBay – must have an MT2 taper for the Viking) | 0.0635mm | WOW. I would have used this but it would have required I used the spanner constantly as the Viking doesn’t have enough resistance when off to hold the spindle in place when you turn the chuck. At $119.99, it’s hard to beat the price. |

| Llambrich JK-130-MT2 (I bought mine off eBay. Pricing can vary tremendously but make sure you are buying from a reputable seller – click here for current listings.) | 0.0655mm | Well, I decided this was good enough at $280. It is a true keyless chuck and you can hold it in position with one hand while adjusting the collar with the other — which is what I wanted. The next step up would have been an Albrecht for even more money. Here’s a link to eBay for new and used Albrecht chucks if you want to go that route. They are supposed to be the best. |

So, I am currently using the Llambrich because of the big price jump up to the Albrecht. I’ve had guys tell me to buy a used Albrecht but I didn’t want to inherit someone else’s problems. Maybe I’ll give a used Albrecht model a try some day where I can return it if it doesn’t test appropriately but I have other things to spend money on at this point.

Some photos from setting up and early use

My Thoughts After Two Months Of Real Use

I honestly can tell you the Nova Viking drill press is one of the best tool purchases I have made. I’ve drilled probably 50-100 grips since I got it plus other parts also – composites and steel mostly.

Why do I like it?

- It’s surprisingly quiet. For whatever reason that was the first thing that popped in my head as I started writing the list of reasons.

- I like being able to turn a dial and adjust the RPM for the drill bit and material I am working with. The Viking has a variable frequency drive so you still have a ton of torque at slower speeds. The speed is changed by adjusting the frequency of the power curve and not by simply starving the motor of power.

- The motor is a beast. My old HF drill would bog down – this one just eats material. It’s actually stunning how powerful it is. I’ve not bogged it down yet. I also watched it snap a piece of composite in a way I had not thought possible with all of that power.

- So, combine all that power and easy-to-set RPM and I am able to drill holes a lot faster. I’d say my time spent drilling almost was cut by almost 30% and that’s just a best guess. I can tell you I know I am getting drilling work done a lot faster overall.

- I really like the auto-start feature. When enabled, the motor turns off when the spindle is returned to the top. The motor turns on as you bring the spindle down. No more spinning bits while changing workpieces so safety increased.

- The spindle and bearings are rock solid – zero play when drilling at angles or at least I sure don’t notice it. When I measure where and test where the bit will hit the surface, that is where the bit hits the surface and then it doesn’t move during the plunge.

- I’ve used the depth indicator a few times when I’ve needed to know when to stop on repetitive pieces. It wasn’t a big reason why I bought the press but it is handy.

I should also point out you can buy all of the parts from Teknatool if something goes wrong plus you can buy a warranty. I’ve always thought warranties tell you a bit about the quality. The shorter the warranty then the more likely things are to break. The longer the warranty then the less likely things are going to break during that duration. Out of the box, the Viking has a decent warranty:

2 Year Full Replacement motor and controller

5 Year Full Replacement mechanical

I went ahead and bought the extended warranty direct from Teknatool just in case plus I felt it was affordably priced.

The Emergency Stop button turned out to be broken during testing and Teknatool replaced it right away along with decent instructions about how to do so. Stuff happens so for a vendor to respond quickly to make things right, I value that. They had no idea who I was or that a blog was going to be written – they just made it right.

Teknatool also has a lot of documentation online if you want to read more about the unit. I sure did and click here for the product page with links to the docs,

Summary

I really like the Nova Viking drill press by Teknatool. Buying it off Amazon meant I saved $100-200 on shipping plus I figured I had Amazon’s customer service if something went wrong. Click here to see the listing on Amazon. Other than a busted E-Stop button, and they sent me a replacement and instructions on how to replace it right away, I have had zero problems. Quality and productivity have both increased with this new drill press as explained above.

If you are looking for a drill press, I’d recommend any of the Teknatool units. I’ve heard nothing but good things about the other models and I would absolutely buy my Nova Viking again.

I hope this helps you out.

Note, I have to buy all of my parts – nothing here was paid for by sponsors, etc. I do make a small amount if you click on an ad and buy something but that is it. You’re getting my real opinion on stuff.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.